Chocolate Hydro 3D Printer

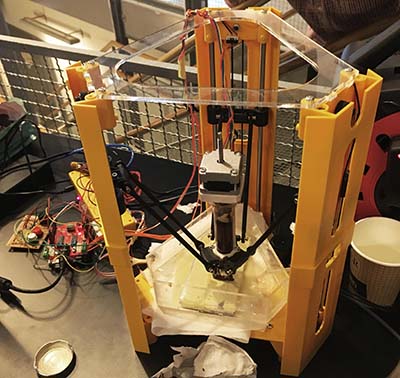

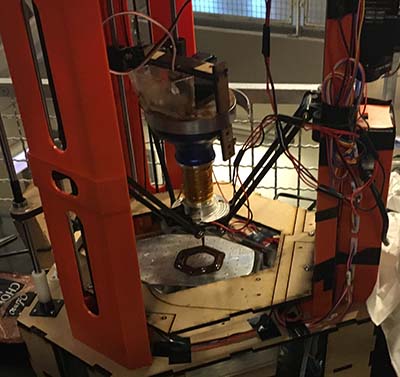

So the challenge for the students was to take this idea and develop it into a fully working proof-of-concept 3D printer. Five student teams were tasked with developing the best way for the system to work. This project was particularly tough as the students only had 6 weeks in which to create a working prototype of the chocolate printer. In order to be able to achieve this within such a tight time-frame, each team was given a low-cost 101Hero 3D printer to hack into their chocolate printers.

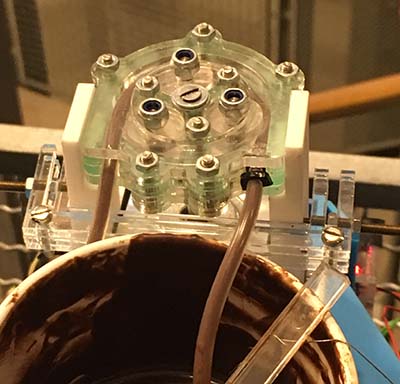

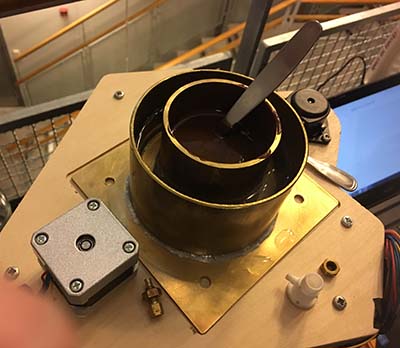

The students were incredibly creative in the number of solutions they tested, both for extruding the chocolate, and for gradually raising the water level after each layer was printed. For the chocolate extruder, one team used a screw-based extruder, 2 teams used peristaltic pumps, and 2 teams used syringe based extruders. For the water raising system some teams used ultrasonic sensors to detect the water level, while others used 2 wires protruding from the print head that, when they made contact with the water triggered the water pump to stop pumping. They also showed great ingenuity in how to melt the chocolate, with one team building a little bain-marie directly on top of their printer.

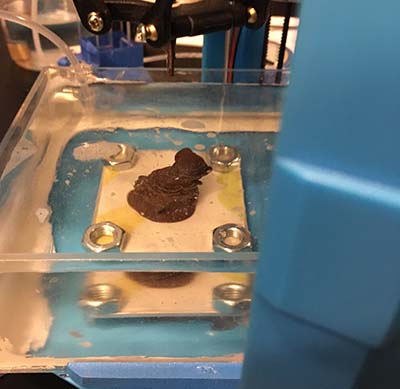

As for all students, there was a steep learning curve in getting familiar with all the digital prototyping technologies they had at their disposal, ranging from CAD to 3D printing, laser and water jet cutting, CNC machining, Arduinos and Raspberry Pi's, etc. It was also interesting to watch their progression as they stated integrating their ideas into the printers and gradually get them to a level where they worked reliably. As with most product development, the project was very iterative where multiple ideas were tested to figure out which one worked best. The picture below shows the gradual progression of testing new ideas and tweaking all the system components to be able to print a little chocolate cat. Remember! This project was just done as a proof-of-concept to show the idea of printing on water could work. The next versions will have thinner layers, smaller print nozzles, greater precision, etc.

The next stage for this project will now be for the next class of students to go from the printers being a proof-of-concept to a fully developed product that prints well and reliably the first time every time... The project was supervised by Olaf Diegel, Giorgos Nikoleris and Johannes Ekdahl Du Rietz. Says Prof. Diegel: "Never have I seen students put so much enthusiasm and energy into solving real technical problems. Their ability to creatively apply and adapt the theoretical knowledge taught to them during their degree in a project is simply astounding!". And, of course, the idea of printing with chocolate is just plain fun, so who wouldn't be excited by working on that? But, ultimately, the proof of the chocolate is in the eating!

|

||||||||||||

copyright 2017, olaf diegel